|

|

|

|

|

|

Part 1 |

An appropriate tone of veneer glue will often fill in this type of defect. VeneerSupplies.com offers light, medium, and extra dark veneer glue in quarts and gallons. Hole filling is especially easy if you use breather mesh in a vacuum press. This because the mesh allows the glue to be pulled through the pin holes. The glue will fill the holed and cure slightly above the surface which allows the user to remove the excess, leaving behind a smooth flat surface ready for finish sanding. If the pin holes are not completely filled after vacuum pressing the panel, a custom wood filler can be made by mixing fine sawdust (such as what you find in the bag on your random orbit or belt sander) with veneer glue. Another option for on-the-spot wood filling is Elmer's Stainable wood glue. This adhesive can be tinted with Transtint liquid dyes to just about any color you can think of. To apply a filler, brush one or two light coats onto any areas that require filling. Sand or scrape the surface when the filler has dried. Obviously, it's important to exercise care to prevent accidentally cutting through the veneer face. Go slowly and watch for changes in the color and texture of the veneer. If you see a change, stop and examine the panel closely. If the veneer is too thin, you may need to do a creative inlay or color that area with a toner in your finish. You might even need to scrap the panel and start fresh if you've sanded completely through. For a glass smooth surface, you'll need grain filler. This is especially useful on coarse-grained veneers like oak and ash. Several grain fillers are commercially available and most take a stain and finish very nicely.

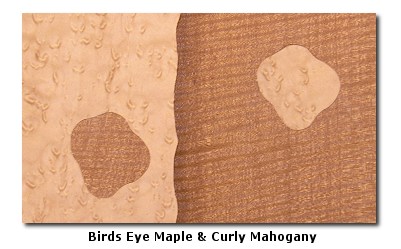

Voids (Large Holes) It is critical that a spritz of veneer softener is sprayed on the veneer surface a minute or two before punching out a defect to make a clean the cut without damaging the tool. Once the softener has been applied, place a piece of soft wood under the defect area on the veneer and use the tool to punch out the defect. It's best to use enough force to make the cut in one strike of the hammer. It takes just a bit a practice to learn the amount of force that is needed. You certainly want to avoid damaging the punch by striking it with too much force, so practice on some scrap veneer starting with a mild hammer strike and build up force until you get a sense of the effort required to get a clean cut. You can now place the keeper veneer over a sacrificial veneer sheet and use the punched-out hole as a window to see the grain on the bottom sheet of veneer. Slide the top veneer over the bottom sheet while looking for an ideal grain pattern that best matches the grain in the top/keeper sheet. Use a pencil to lightly mark the location on the bottom sheet once you've found an area that has a pleasing grain match. Set the top sheet aside and then spray the selected are sheet on the sacrificial sheet with veneer softener. Let it sit for a minute or two and then place a piece of soft wood under the sacrificial veneer. Align the punch with the pencil outline and strike the punch with a hammer. Now set the patch into the hole in the keeper veneer and apply a small piece of veneer tape to the top of the veneer sheet to hold the patch in place while being pressed. The tape can easily be removed after the veneer has been glued to a substrate.

Some books suggest that the edge of a piece of galvanized pipe can be sharpened and then bent in a vice to make an irregular shape cutting edge. I've tried this many times and never had any luck making a perfect cut. Even some of the pictures in these books show evidence of a rough and uneven edge. You've got to wonder how sharp and durable can the edge be made on a piece of non-hardened steel. Bark Patches

Lay a damp paper towel under and over the split area on the veneer. Do not put water directly on the veneer but be sure to moisten the entire surface of the paper towels. The added moisture will help to gradually expand the wood cells around the split and which will decrease the gap. It's best to place a piece of wax paper over and under the paper towels. Then place a board on top with some weight on it. This weighted board will minimize any wrinkling that can occur from the added moisture. The wax paper prevents the moisture from being wicked into the weighted board. Allow this to sit for 30 minutes. If the veneer is capable of being repaired, the width of the split will have decreased dramatically. When the split has been minimized via moisture, apply no-hole veneer tape across the split on the face side of the veneer. To get the best results, place tape on one side of the split then pinch the end of the tape between the veneer and your thumb. Then gently pull the tape tightly across the split as you use finger pressure to close any remaining evidence of this imperfection. When the veneer and tape have dried, adhere the veneer to your substrate as soon as possible to prevent any further splitting. Finished Panel Cracks & Splits Epoxy dries clear and in some cases you may find this advantageous. However, if a wood tone is needed, you'll need to add some sanding dust to the epoxy (preferably of a species similar in color to the veneer). My random orbit sander provides me with a fine powder-like dust that blends well into epoxy. Keep in mind that epoxy will not absorb stain. If you are planning to stain your project, you'll need to apply sanding dust that resembles the color of the stain you'll be using. |

|

|

|

The

easiest way to repair large holes is with a veneer punch also known as a cloud punch.

The

easiest way to repair large holes is with a veneer punch also known as a cloud punch.

After

pressing the veneer, any remaining blemishes can be filled in with a

stainable wood putty. But my favorite method is to use epoxy which works

exceptionally well if you don't plan to stain the finished project.

The key is to use 5 minute "quick set" epoxy and add just

a bit more of the hardener. Allow an hour or more for it to fully harden

and then scrape or sand it flush. Be careful that you don't sand through

the veneer face. If the sand gums up with epoxy, wait longer for it

to completely cure.

After

pressing the veneer, any remaining blemishes can be filled in with a

stainable wood putty. But my favorite method is to use epoxy which works

exceptionally well if you don't plan to stain the finished project.

The key is to use 5 minute "quick set" epoxy and add just

a bit more of the hardener. Allow an hour or more for it to fully harden

and then scrape or sand it flush. Be careful that you don't sand through

the veneer face. If the sand gums up with epoxy, wait longer for it

to completely cure.